By Antor Hossain

📧 antor@antor.xyz | 🌐 antor.xyz

Introduction

For UK retailers, 2025 marks another turning point. Inflation has eased compared to its peak, but many input costs remain stubbornly high. At the same time, regulation around sustainability and product safety is tightening. Add to that consumer demands for speed and ethical transparency, and the sourcing puzzle becomes more complex.

Merchandisers are at the front line: they must ensure products are delivered on time, at the right cost, under evolving environmental and regulatory constraints, without compromising quality or reputation.

Here are the top three sourcing challenges UK retailers face — and how to overcome them.

1. Cost Pressures: Labour, Input and Logistics Inflation

The Challenge

- Labour costs: The UK National Living Wage has risen, and employment taxes like National Insurance contributions are heavier. This affects both UK retailers and overseas suppliers.

- Material & energy costs: Raw materials, packaging, and energy remain volatile.

- Freight disruptions: Geopolitical risks, port congestion, and fuel price volatility increase landed costs.

Example

- According to RSM UK, the full implementation of packaging Extended Producer Responsibility (EPR) and rising wages are among the top cost pressures retailers face in 2025.

- The British Retail Consortium (BRC) reports that nearly 9 in 10 retail CFOs rank “tax and regulatory burdens” — including employment costs — among their top three concerns.

How to Overcome It

- Diversify sourcing regions to balance cost and reduce shipping risk.

- Negotiate long-term contracts with suppliers to secure pricing stability.

- Adopt value engineering to optimize materials and packaging.

- Use supply chain analytics to monitor costs and forecast risks.

2. Sustainability & Compliance

The Challenge

- Textile Extended Producer Responsibility (EPR): Coming into force in the UK, making retailers accountable for end-of-life textile waste.

- Packaging regulation: Stricter reporting and recycling requirements under UK’s packaging EPR.

- Traceability & labour laws: Retailers must comply with rules on green claims, modern slavery, and chemical safety.

Example

- The Marsh & McLennan 2025 UK Retail Leaders Report shows that while sustainability is a priority, most retailers admit they are not yet effective in reaching their targets.

- Submissions to UK Parliament by the Parker Lane Group have pushed for stricter textile labelling and recycling schemes.

How to Overcome It

- Source certified suppliers (OEKO-TEX, GOTS, Sedex, SA8000).

- Invest in traceability tools such as digital product passports.

- Design with sustainability in mind — recyclable fibers, minimal waste.

- Implement recycling or take-back programs to meet EPR requirements.

- Engage with regulators & industry bodies to anticipate upcoming laws.

3. Lead Time & Speed to Market

The Challenge

- Consumers demand speed: Fast fashion cycles and frequent drops create pressure.

- Supply chain disruptions: Weather, geopolitics, and labour shortages add unpredictability.

- Inventory risk: Too much stock risks waste; too little risks lost sales.

Example

- Supply Chain Digital warns UK retailers that dependency on a few overseas suppliers creates vulnerability. Restructuring is needed for resilience.

- Some UK food retailers have reduced product ranges to simplify sourcing and ensure reliable deliveries — a lesson apparel retailers can apply.

How to Overcome It

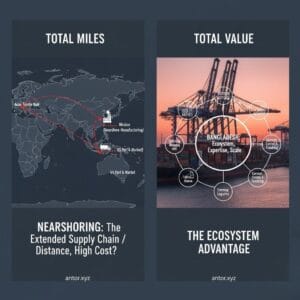

- Near-shoring strategies (Eastern Europe, Turkey, North Africa) to reduce transit times.

- 3D sampling & digital prototyping to cut approval cycles.

- Flexible supplier contracts to allow smaller or split orders.

- Demand forecasting & analytics to predict trends and align inventory.

- Multi-route logistics planning to avoid single points of failure.

Conclusion

2025 is shaping up as a year in which the sourcing bar for UK retailers is higher in multiple dimensions. It’s no longer enough to source cheaply — sourcing must be responsible, fast, and flexible.

Merchandisers who anticipate regulation changes, build supplier resilience, and harness digital tools will transform these challenges into opportunities. By balancing cost, sustainability, and speed, UK retailers can thrive in this competitive market.

👉 If you’re looking for apparel development, sourcing, and production support, feel free to connect with me at antor@antor.xyz or visit antor.xyz.

References

- RSM UK – Retail Industry Outlook 2025

- British Retail Consortium – Corporate Affairs Report 2025

- Marsh & McLennan – UK Retail Leaders Report 2025

- UK Government – Extended Producer Responsibility Guidance

- Supply Chain Digital – UK Trade Challenges 2025