I speak with global buyers every day, and the main topic is nearshoring apparel. The pressure to move production closer to home—to Mexico, to Turkey, to Eastern Europe—is immense. The logic seems simple: ‘closer equals faster,’ and as major industry reports like McKinsey’s State of Fashion highlight, brands are under increasing pressure to reconfigure their global supply chains.

As a manufacturing leader who manages complex global supply chains for a living, I believe this reactive shift is a dangerous illusion. Buyers are chasing ‘faster shipping’ and walking straight into a ‘total value’ trap. Before you move your nearshoring apparel sourcing, you must ask 3 critical questions that many new ‘nearshore’ partners probably can’t answer.

1. The ‘Ecosystem’ Cost: A Hidden Flaw in Nearshoring Apparel

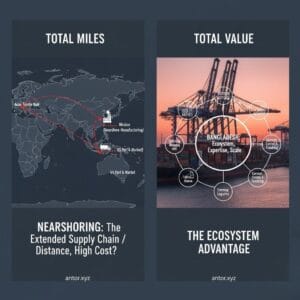

A factory in Mexico may be just three days away from your distribution center by truck. This sounds amazing, but ask them this: where do they get their high-performance, recycled, specialized fabric?

The answer, in almost every case, is that they import it… from Asia.

Suddenly, you haven’t shortened your supply chain at all; you’ve just added a new, expensive, and slow stop. You are now paying for that fabric to be shipped across the ocean to your nearshore partner, only to then be shipped back across an ocean to your final market.

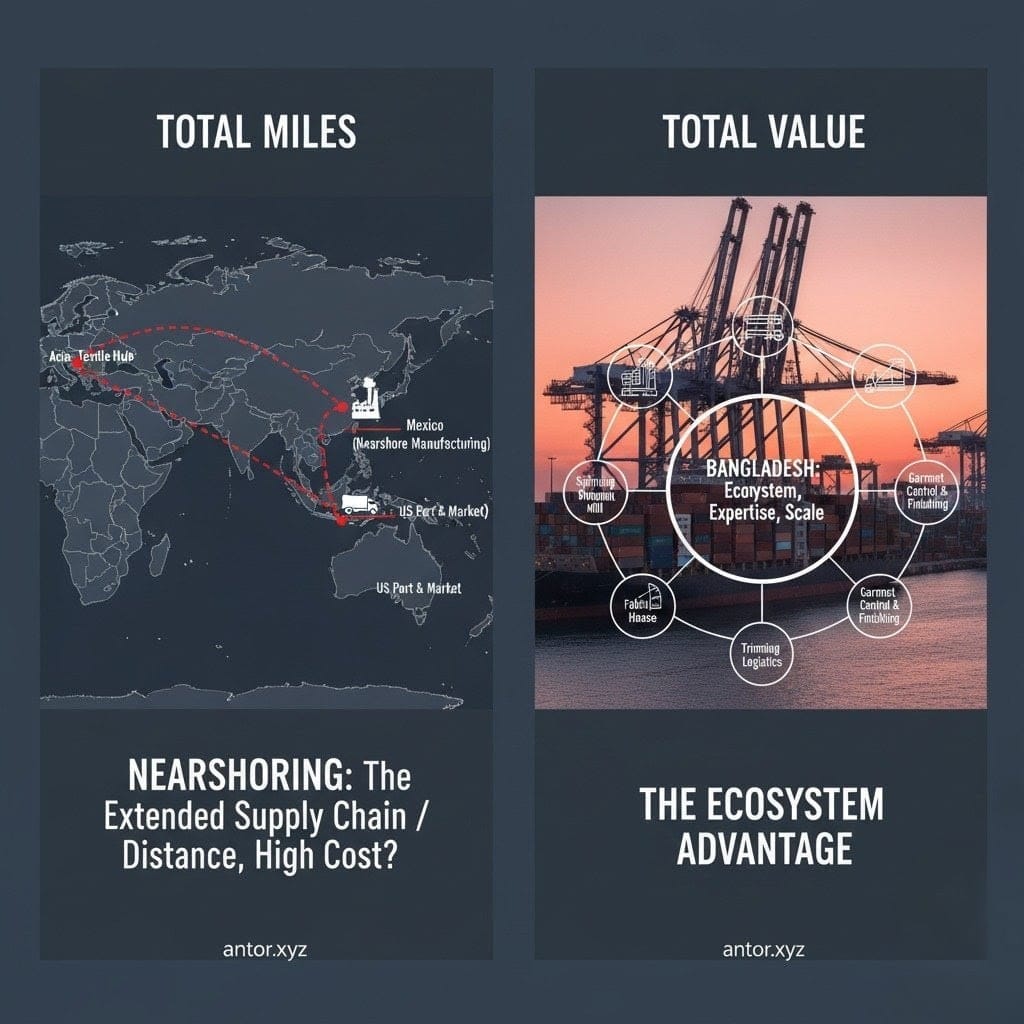

This is where the power of Bangladesh’s mature vertical ecosystem becomes clear. We have the spinning mills, the fabric mills, the dye houses, and the trim factories all within a few kilometers of each other. Our total lead time – from raw yarn to finished garment – is often significantly faster than a ‘nearshore’ factory that has to wait 30-40 days for its core materials to arrive from our continent.

2. The ‘Expertise’ Cost: Can Your Nearshoring Partner Scale Complex Apparel?

Making 5,000 basic t-shirts is easy. Almost any factory can do that.

Making 1 million units of a technical jacket with 120 components, bonded seams, 5-color printing, and strict compliance standards is not.

Expertise at scale is the real product you are buying from Bangladesh. Our workforce, our technicians, and our line managers have 20+ years of specialized, generational experience in making complex apparel. This deep knowledge isn’t just a “nice to have” – it is the critical element that prevents catastrophic quality failures, ensures consistency across a million-unit run, and guarantees your product hits its target margin.

This level of expertise in nearshoring apparel production simply cannot be built in a new country overnight. When you move to a new region, you are often sacrificing decades of know-how for a shorter shipping route. It’s a trade that rarely pays off.

3. The ‘Scale’ Cost: The Growth Limit of Reactive Nearshoring Apparel

Let’s say your nearshore partner handles your 100,000-unit test order perfectly. The product is a massive success. What happens when your test is a success and you need 3 million units of nearshoring apparel for the next season?

This is the moment the nearshoring model often collapses. Your partner doesn’t have the capacity. They can’t find the additional skilled labor. They can’t secure the extra fabric. They cannot scale with you.

Bangladesh is built for scale. Our capacity is proven, reliable, and unmatched globally. We are a partner that can grow with you, not hold you back. We have the infrastructure and the workforce to take you from a 100,000-piece test to a 10-million-piece program, all while maintaining the same level of quality and consistency.

My Personal Advice: ‘Smart-Shoring’ is the Future of Nearshoring Apparel

Do not be reactive. Be strategic.

The question you ask should not be, “How close is this factory?” The question must be, “How capable is this partner?“

The future of nearshoring apparel is not about ‘near’ or ‘far.’ It’s about ‘smart-shoring. Smart-shoring means partnering with the most capable, vertically integrated, and proven experts in the world, wherever they are.

For the apparel industry, that expertise, ecosystem, and scale remains right here.

I am on the ground in Bangladesh, building these “smart” supply chains every day. What is your experience with nearshoring? Is it hype, or is it a real solution?

I would value your perspective in the comments.