Last updated: December 23, 2025

How to brief Bangladesh denim factory teams the right way is the difference between a clean 1–2 sample cycle and weeks of delays. This buyer-first playbook gives you a factory-ready brief for woven and denim—tech pack, BOM, approvals, sampling, QC/AQL, packaging, Incoterms, and copy-paste templates you can send today.

Key takeaways (save 60 seconds)

- Send a complete brief on Day 1: tech pack + BOM + standards + packaging + Incoterm.

- Lock approvals in the right order: color/print/wash → PP sample → bulk.

- Define QC early: AQL levels + defect examples = fewer disputes.

- Packaging and carton markings can delay shipments—include them in the brief, not “later.”

- Version control prevents chaos: one file owner, one comment sheet, clear naming.

Table of Contents

- Quick Start: what to send in the first email

- The Factory-Ready Brief Pack (Tech Pack + BOM + Decision Pack)

- Woven vs Denim: what must be different

- Approvals: lab dips, strike-offs, denim wash

- Sampling roadmap + what each stage “locks”

- Simple TNA (Time & Action) that actually works

- Pre-Production Meeting (PPM) checklist

- Quality: AQL + defect language buyers and factories share

- Testing: what to request (and when)

- Packaging & labeling: avoid shipment holds

- Incoterms: define responsibility early

- Communication & version control (world-class workflow)

- Copy-paste templates (RFQ, follow-up, sample comments)

- Next step: Send your brief (RFQ)

- FAQ

How to brief bangladesh denim factory: Quick Start checklist

Copy this checklist, attach your tech pack + BOM, and you’ll cut follow-up questions dramatically.

If you only have 15 minutes, send this “minimum viable brief” pack. It’s enough for serious costing and a clean first sample.

- Tech pack PDF (flats, construction, POMs+tolerances, grading, colorways)

- BOM (fabric, trims, labels, packaging)

- Color/print/wash standards (Pantone/swatches, artwork files, wash reference)

- Target order quantity (even an estimate + size ratio)

- Target FOB range (or say “open costing”)

- Ship window (target ex-factory date)

- QC expectation (AQL levels + any non-negotiables)

- Incoterm + named place (FOB/FCA/etc.)

Buyer-first rule: Factories move faster when they are not forced to guess. Your brief removes guessing.

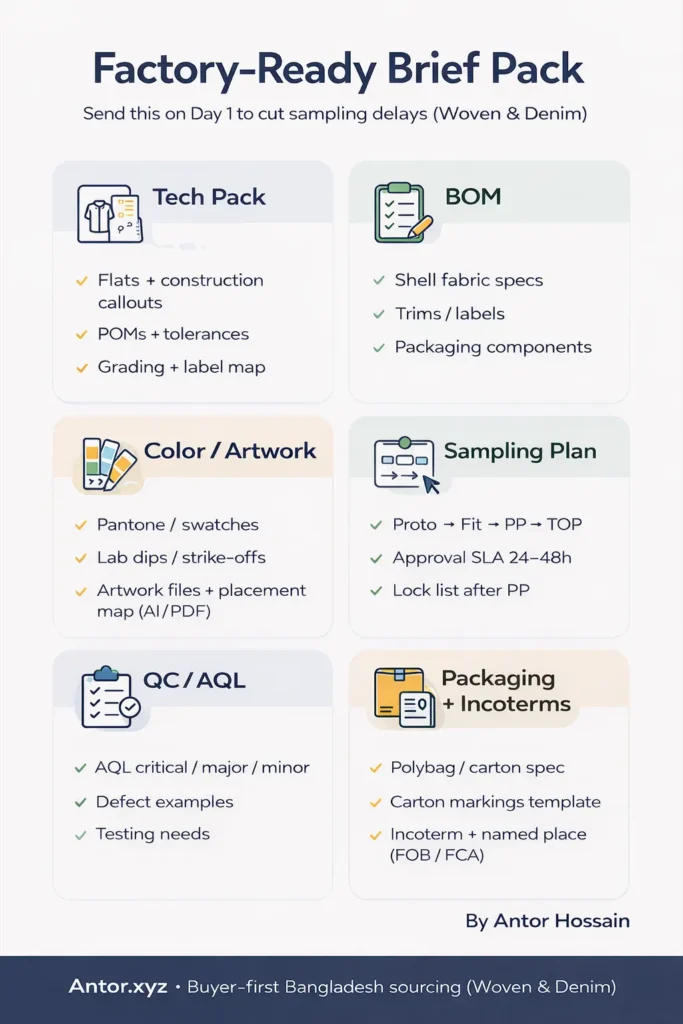

The Factory-Ready Brief Pack (send on Day 1)

A factory-ready brief is a single source of truth the factory can use to cost, sample, and execute without assumptions.

1) Tech pack (your blueprint)

Your tech pack should answer: What is it? How is it constructed? How do we measure it? What materials are used? What are the approvals?

Tech pack checklist

- Tech flats: front/back + inside views if needed

- Construction callouts: seams, stitch type, seam allowance, SPI guidance, reinforcements

- POMs (Points of Measure): where/how to measure, with diagrams

- Tolerances: acceptable variation per key POM

- Grading: base size + grade rules (or a grade table)

- Colorways: list + reference standards

- Label placement map: main/size/care/country of origin (as needed)

Example POM list (use as a QA check)

Woven shirt POM examples: chest 1″ below armhole, shoulder, sleeve length, bicep, cuff opening, collar point, collar stand height, front length, sweep, placket width, pocket position.

Denim jeans POM examples: waist, high hip/low hip, front rise, back rise, thigh, knee, leg opening, inseam, outseam, yoke height, pocket opening, waistband height.

2) BOM (Bill of Materials): your production recipe

A BOM is the complete list of everything needed to make the garment—including trims, labels, and packaging—so nothing becomes a last-minute blocker.

BOM checklist

- Shell fabric: composition, GSM/oz, weave, finish, shrinkage expectation

- Secondary materials: lining, pocketing, fusing/interlining

- Trims: zipper/buttons/rivets/hardware (finish + color)

- Thread: type (poly/cotton core-spun), ticket number if you use it

- Label set: main/size/care/country of origin as required

- Packaging: polybag spec, size sticker placement, carton spec, carton marking fields

3) Decision Pack (what factories need to quote correctly)

- Target FOB range (or confirm “open costing”)

- Order quantity + color/size split (even estimated)

- Ship window (target ex-factory date)

- Compliance needs (only what your buyer/market requires)

- Incoterm + named place (FOB Chattogram / FCA Dhaka, etc.)

Factory-Ready Checklist (quick table)

| Item | What to include | What it prevents |

|---|---|---|

| Tech pack | Flats, construction notes, POMs+tolerances, grading, colorways | Extra sample rounds due to unclear specs |

| BOM | Fabrics, trims, labels, packaging (with specs) | Missing components at bulk start |

| Standards | Color/print/wash standards + approval method | Approval loops with vague feedback |

| QC | AQL levels + defect examples + any “zero tolerance” items | Inspection disputes + rework |

| Packaging | Polybag/carton spec + carton markings template | Repacking / shipment holds |

| Incoterms | Incoterm + named place + who books freight/docs | Late-stage logistics confusion |

Woven vs Denim: what must be different in your brief

Woven (shirts, dresses, workwear)

- Fusing/interlining: where used + stiffness expectation (collar/placket/cuff)

- Placket/collar/cuff specs: widths, shapes, edge stitching, button spacing

- Stitch + seam clarity: SPI guidance, seam type, reinforcements

- Dimensional stability: how you want garments measured and any shrinkage limits

- Critical details to call out: pocket placement, collar roll, buttonhole length/density, cuff opening

Denim (jeans, jackets, chinos with wash)

- Fabric: oz/yd², stretch %, recovery expectation

- Wash intent: rinse/enzyme/stone/bleach/tint/overdye + reference photos

- Shade tolerance: define acceptable variation (shade band)

- Hardware exactness: rivet/button finish changes the look—spec it clearly

- Risk to address: shade migration, crocking/rub-off, skew, shrink after wash

Approvals: lab dips, strike-offs, denim wash (where weeks disappear)

Lab dips (solid color approval)

A lab dip is a dyed swatch submitted for color approval before bulk dyeing. Approvals go faster when the standard is clear and feedback is specific.

Lab dip approval tips

- Provide a clear standard (Pantone code or physical swatch)

- Specify how you judge: daylight/lightbox preference

- Feedback like “too red / too dull / too dark” is actionable; “not ok” is not

Strike-offs (print approval)

A strike-off is a printed fabric sample used to approve print appearance before bulk printing. Always confirm scale, placement, and color.

Strike-off pack (send together)

- Artwork files: AI/PDF + hi-res PNG

- Placement map with measurements from reference points

- Color standard (Pantone or swatch)

- Approval criteria: scale tolerance + placement tolerance

Denim wash approvals (wash + shade + handfeel)

Denim requires a “look” approval. Lock wash intent early so bulk doesn’t drift.

- Provide 2–4 reference photos (front/back + detail)

- Approve a wash standard: shade band + handfeel expectation

- Confirm whether whiskers, scraping, spray, or tinting is allowed

Sampling roadmap + what each stage “locks”

Sampling works when each stage locks a specific risk—then you stop changing that risk later.

| Sample stage | What it’s for | What should be locked |

|---|---|---|

| Proto | Visualize design intent | Overall silhouette, key construction approach |

| Fit | Fit balance + measurements | POM method + key measurements + fit comments |

| PP (Pre-Production) | Readiness for bulk | Final fabric/trims, approved standards, packaging, QC plan |

| TOP | Early bulk consistency | Bulk performance matches approved sample |

World-class sample comments (reduce email loops)

- One comment sheet (Google Sheet or PDF) with: issue, photo reference, required action, priority, owner, due date.

- Use “must change” vs “nice to have.” Factories move faster when priorities are clear.

- Keep a “locked items list” after PP approval. Any change after that should note cost/time impact.

Simple TNA (Time & Action) that actually works

You don’t need a complicated calendar. A simple “Week-by-week” plan is enough to protect ship date.

| Week | Buyer action | Factory action | Dependency |

|---|---|---|---|

| Week 1 | Send brief pack + standards | Costing + sample plan + questions list | Complete tech pack + BOM |

| Week 2 | Return comments fast | Proto/fit sample development | Clear feedback + decisions |

| Week 3 | Approve standards (color/print/wash) | Material booking + PP prep | Approved standards |

| Week 4 | Approve PP sample + packaging | Bulk start + inline QC plan | PP approval |

Speed lever: Your response time is part of lead time. Returning comments quickly is the cheapest way to ship on time.

Pre-Production Meeting (PPM) checklist

A PPM prevents “surprises” right before bulk. This is where you align on the final version of everything.

PPM agenda (buyer version)

- Confirm final tech pack version + closure of comments

- Confirm approved lab dips / strike-offs / wash standard

- Confirm fabric & trims in-house dates

- Confirm PP sample approval + golden sample handling

- Confirm QC plan: inline checks + final inspection

- Confirm AQL levels + defect examples (critical/major/minor)

- Confirm packaging/carton markings + label rules

- Confirm Incoterm + named place + who books freight/docs

- Set response SLA (who answers within 24 hours)

Quality: AQL + defect language buyers and factories share

AQL in plain language

AQL (Acceptance Quality Limit) is an inspection approach that sets acceptable defect levels in a sampled inspection lot, often classified as critical / major / minor. Many brands align sampling plans with ISO 2859-1 or ANSI/ASQ Z1.4, but your exact levels should match your buyer requirements.

What to include in your brief (minimum)

- Your AQL levels (critical/major/minor)

- “Zero tolerance” issues if any (e.g., needle damage, wrong labeling, safety hazards)

- Defect examples for your product (so classification is consistent)

Example defect language (use and edit)

- Critical: safety hazard, sharp object, contamination, severe damage

- Major: open seam, wrong measurement beyond tolerance, wrong label, obvious shade mismatch, broken zipper

- Minor: small thread ends, minor puckering within tolerance, slight print misalignment within tolerance

Testing: what to request (and when)

Testing should match your product risk and target market. Keep it simple: request only what matters for your buyer.

Common tests buyers request (by risk)

| Risk | Typical focus | Best time to request |

|---|---|---|

| Shrink / size drift | Dimensional stability after wash | Before PP approval / before bulk |

| Color fastness | Wash, rubbing (crocking), perspiration | Before bulk (especially denim/dyed goods) |

| Construction strength | Seam strength, attachment strength (buttons) | PP stage / early bulk checks |

| Appearance | Pilling, spirality, skew (category-dependent) | Development stage if risk is high |

Tip: If your buyer has a vendor manual, follow that. If not, agree “must-pass” tests in the PPM.

Packaging & labeling: avoid shipment holds

Packaging is one of the most common “last-week surprises.” Put it in the brief from Day 1.

Packaging checklist

- Packing method: flat pack / hanger pack

- Polybag: thickness, warning text if needed, size sticker placement

- Carton spec: carton size limits, max weight target, qty per carton

- Carton markings template: PO, style, color, size, qty, carton no., country of origin

- Label rules: care/country of origin/size/brand as required

Carton marking example (edit to your format)

PO: ____ Style: ____ Color: ____ Size: ____

Qty/ctn: ____ Carton no.: ____ of ____ Made in: Bangladesh

Incoterms: define responsibility early

Incoterms clarify tasks, costs, and risk between buyer and seller. Use them to remove confusion before shipping discussions start.

What to specify

- Incoterm + named place: e.g., FOB Chattogram / FCA Dhaka

- Who books freight: buyer vs seller

- Who handles documents: invoice, packing list, export support requirements

- Ship method: sea/air/courier (for samples)

Communication & version control (world-class workflow)

Most delays are communication failures, not manufacturing failures. Use this workflow and your factory will move faster.

1) Version control that prevents chaos

- One file owner (buyer side)

- One comment sheet (single source for feedback)

- One naming system:

STYLE123_TechPack_v07_2025-12-23.pdfSTYLE123_BOM_v03_2025-12-23.xlsxSTYLE123_SampleComments_Fit1_2025-12-23.pdf

2) Response SLA

- Factory questions answered within 24 hours (ideal)

- Sample comments returned fast (your speed = lead time)

3) Locked items list (after PP approval)

- Final fabric + trims

- Approved standards (color/print/wash)

- Packaging + carton markings

- QC/AQL plan

Copy-paste templates (RFQ, follow-up, sample comments)

Template A: RFQ / factory brief message

Subject: Factory Brief — [Style Name] / [Woven Shirt or Denim Jean] — Target Ship [Date]

1) Product

Category: [ ]

Fit: [slim/regular/relaxed] + target market [EU/US/UK/etc.]

Season/use: [workwear/fashion/basic]

2) Order & targets

Estimated order qty: [ ] pcs (initial) + repeat potential

Sizes + ratio: [ ]

Target FOB: [ ] (or “open costing”)

Target ex-factory / ship window: [ ]

3) Tech pack

Attached: Tech pack v[ ] dated [ ]

Base size: [ ]

Tolerances: [ ]

Grading: [attached / to confirm]

4) Fabric

Shell fabric: composition / GSM or oz / weave / finish

Shrinkage expectation/limit: [ ]

Colorways: [list]

5) BOM (trims, labels, packaging)

BOM attached: yes/no

Hardware details (if denim): finish/color references [photos/links]

6) Color / artwork

Lab dip required? yes/no — Standard: [Pantone / swatch]

Print? yes/no — Strike-off required? yes/no

Artwork files attached: AI/PDF + placement map

7) Denim wash (if denim)

Wash intent: [rinse/enzyme/stone/bleach/tint/overdye]

Target shade range: [ ]

Handfeel expectation: [ ]

Wash approval required: yes/no

8) QC & testing

AQL: Critical [ ], Major [ ], Minor [ ]

Key tests: [shrinkage, colorfastness, rubbing/crocking, etc.]

Inspection: [inline/final/3rd party if any]

9) Packaging

Packing method: [flat/hanger]

Polybag: [spec] + size sticker placement [ ]

Carton: max weight target [ ] kg; carton markings template attached: yes/no

10) Shipping

Incoterm + named place: [ ]

Destination: [city/country]

Documents needed: [invoice, packing list, etc.]

11) Next steps

Please confirm within 24–48h:

1) Costing + MOQ assumptions

2) Sample timeline (proto → fit → PP → TOP)

3) Fabric/trims lead-time risks

4) Questions list (single document)

Template B: Follow-up (when factory is slow)

Subject: Follow-up: [Style] — please confirm costing + sample plan

Hi [Name],

Following up on the attached brief for [Style]. Please confirm:

1) Estimated FOB with MOQ assumptions

2) Sample timeline (proto/fit/PP)

3) Any missing inputs you need from us

We can reply to questions within 24 hours to keep the timeline moving.

Thanks,

[Your Name]

Template C: Sample comments (fast and clean)

Subject: Sample Comments — [Style] — [Proto/Fit/PP] — v[ ]

Hi [Name],

Please find attached the single comment sheet with photos and required actions. Priority items are marked “MUST.”

Kindly confirm updated sample submission date once changes are implemented.

Thanks,

[Your Name]

Next step: Send your brief (RFQ)

Send your tech pack + brief and we’ll route it to compliant Bangladesh partners for your product category:

Free download: Tech Pack Checklist

Related reading

- MOQ & Pricing in Bangladesh Woven & Denim Garments

- Bangladesh Woven & Denim Sourcing Guide 2026

- Bangladesh vs China vs Turkey for Woven & Denim

External references (for buyers)

- Incoterms® rules — International Chamber of Commerce (ICC)

- ISO 2859-1 overview — acceptance sampling indexed by AQL

- ANSI/ASQ Z1.4 — sampling procedures for inspection by attributes

FAQ

What’s the minimum I should send for costing?

Send a tech pack (flats + construction + POMs + tolerances) plus a BOM (fabric/trims/labels/packaging) and your estimated order quantity + ship window. Without these, costing becomes guesswork.

Lab dip vs strike-off: what’s the difference?

A lab dip is for solid color approval before bulk dyeing. A strike-off is for print approval before bulk printing.

What is a PP sample?

A pre-production (PP) sample is made with final materials and trims to confirm readiness before bulk manufacturing.

What is AQL and why does it matter?

AQL sets acceptable defect levels in a sampled inspection lot (critical/major/minor). It reduces inspection disputes because acceptance criteria are agreed in advance.

Do I need to include packaging in the first brief?

Yes. Packaging and carton markings are common causes of last-week delays. Including them early prevents repacking and shipment holds.

Note: This guide is educational and does not replace your buyer contract, technical standards, or required shipping documentation.

One Response