In today’s fast-paced fashion landscape, speed is everything. But when rushing product development, many apparel brands face the challenge of balancing timelines with uncompromised quality. The good news? With the right strategies, global apparel brands can accelerate development cycles while maintaining product excellence.

Below are three practical tips that decision-makers, learners, and professionals in the apparel industry can immediately apply:

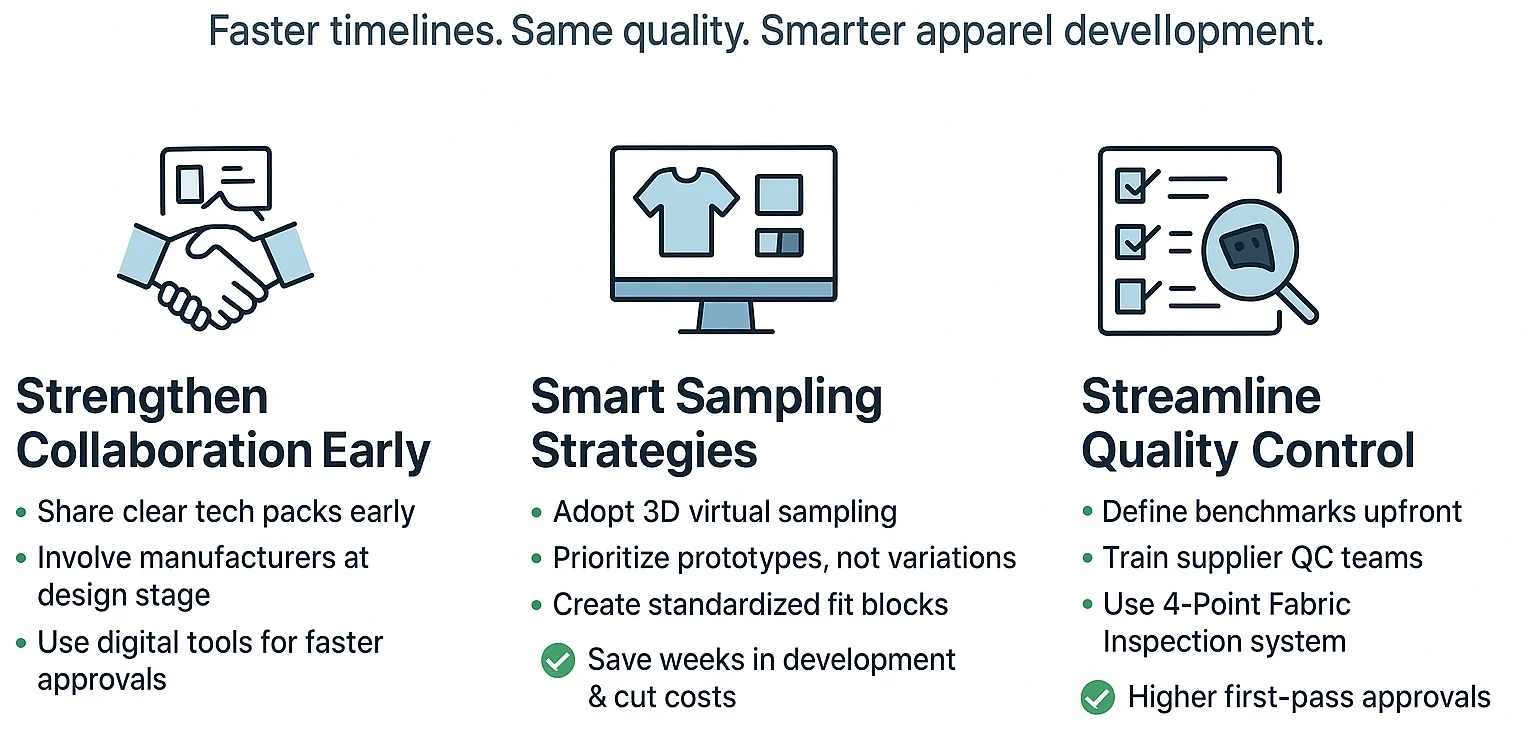

1. Strengthen Collaboration With Manufacturers Early

The earlier a brand aligns with its supply chain partners, the fewer delays will occur later.

- Share tech packs upfront – A complete and clear tech pack avoids misinterpretation during sampling.

- Engage suppliers in the design stage – Manufacturers can flag feasibility issues and suggest cost-effective alternatives before sampling begins.

- Leverage digital communication tools – Video calls, digital approvals, and cloud-based platforms cut down waiting times for feedback.

Result: Reduced sampling rounds, smoother development flow, and quicker market readiness.

2. Use Smart Sampling Strategies

Sampling is often the biggest bottleneck in product development. Optimizing this stage can save weeks.

- Adopt 3D virtual sampling – Tools like CLO3D and Browzwear help visualize designs digitally, reducing the need for multiple physical samples.

- Prioritize prototypes – Start with one perfect sample instead of developing multiple variations at once.

- Establish fit blocks – Standardized base patterns for recurring silhouettes speed up fit approval across collections.

Result: Faster sampling turnaround, lower costs, and consistent quality.

3. Streamline Quality Control From Day One

Waiting until production to focus on quality often leads to rework and delays. Instead, embed QC early.

- Set clear quality benchmarks – Define GSM, shrinkage tolerance, stitching standards, and finishing requirements upfront.

- Train vendor teams – Ensure suppliers’ QC teams align with your brand’s expectations.

- Implement a 4-Point Fabric Inspection system – Catch defects before cutting, preventing wasted time and fabric.

Result: Fewer surprises during production, higher first-pass approval rates, and improved brand reliability.

Final Thoughts

For global apparel brands, accelerating product development is not about cutting corners—it’s about building smarter systems, using the right tools, and collaborating effectively. By aligning early with manufacturers, optimizing sampling, and embedding quality control, brands can achieve faster timelines without compromising on product excellence.

If you’re looking to develop and produce apparel efficiently while maintaining top-tier quality, I’d be happy to support.

Contact me at antor@antor.xyz or visit antor.xyz.