Bangladesh garment lead time MOQ planning is easier when you split timelines into development, production, and logistics. This 2026 buyer guide covers denim and woven programs with a 7-step timeline, MOQ stack breakdown, and RFQ checklist.

If you’re sourcing denim or woven garments from Bangladesh, this guide helps you estimate a realistic MOQ and lead time (development → bulk → ex-factory → shipping), and avoid the most common delays.

Quick answer (TL;DR)

- Repeat orders usually move faster than new styles (fewer approvals).

- Lead time = development + production + logistics. Most delays happen in approvals, fabric booking, and capacity planning.

- MOQ is not one number — it’s a stack (fabric mill MOQ + dye/finish + wash + trims + packing).

- Best practice: add a buffer and confirm timelines by Incoterm (FOB vs CFR vs DDP).

Last updated: 2026-01-13

Contents

- What “lead time” really means

- Lead time timeline (concept → ex-factory)

- Typical ranges by product (woven vs denim)

- MOQ explained as a stack (why suppliers say “no”)

- How to reduce MOQ and shorten lead time

- Buyer checklist (copy/paste)

- FAQs

What “lead time” really means (and what buyers miss)

In apparel sourcing, “lead time” is often quoted as one number — but in reality it has three parts. If you separate them, you can predict delays and negotiate timelines properly.

| Part | What it includes | What causes delays most |

|---|---|---|

| Development lead time | Tech pack review, sampling, fit rounds, lab dips, trims approvals, PP sample | Slow approvals, missing details, fabric/trim changes |

| Production lead time | Fabric booking, cutting, sewing, washing (denim), finishing, packing, final inspection | Fabric availability, line capacity, wash capacity, quality rework |

| Logistics lead time | Inland transport, port processing, ocean/air transit (depends on Incoterm) | Port congestion, documentation, space availability |

Rule of thumb: when a supplier says “45 days,” confirm if they mean ex-factory (production only) or delivery to your warehouse (production + logistics). Your Incoterm (FOB/CFR/DDP) changes the real timeline.

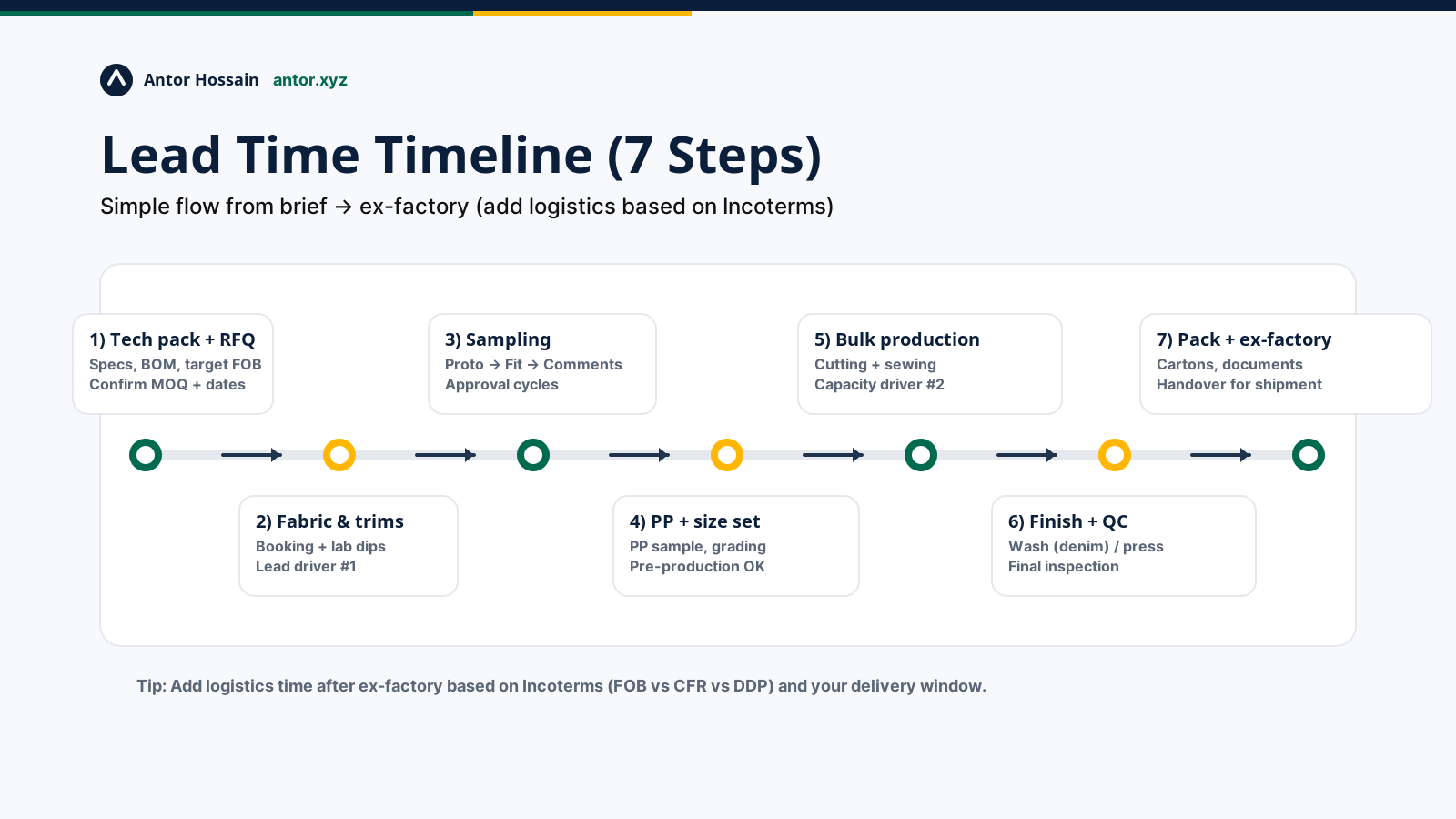

Lead time timeline (concept → ex-factory)

This 7-step timeline is the fastest way to align your team and supplier. Use it to track dates, responsibilities, and where you need buffer.

7 steps checklist (copy/paste into your tracker)

- Step 1: Tech pack + target price + order quantity confirmed

- Step 2: Sample & fit approvals (including measurement + construction)

- Step 3: Fabric & trims approvals (lab dips, strike-offs, trim cards)

- Step 4: Pre-production (PP) sample + packing approval

- Step 5: Bulk production (cutting → sewing → wash for denim)

- Step 6: Finishing + final inspection + carton sealing

- Step 7: Ex-factory + shipment booking (Incoterm defines what’s next)

Bangladesh garment lead time MOQ: typical ranges by product (woven vs denim)

Below are typical planning ranges buyers use for Bangladesh. Your actual MOQ and lead time will change based on fabric availability, approvals speed, wash complexity (denim), and factory capacity. Use this table to set expectations before requesting quotes.

How to read this: “Development” = sampling + approvals. “Bulk” = fabric booking + production to ex-factory. Logistics is separate and depends on Incoterm.

| Product | MOQ (typical starting point) | Development lead time | Bulk lead time (to ex-factory) | Main risk drivers |

|---|---|---|---|---|

| Woven shirts (casual / formal) | Often 1,000–3,000 pcs per style (lower if stock fabric) | ~2–4 weeks | ~45–75 days | Fabric booking, fit rounds, trims approvals |

| Woven chinos / trousers | Often 1,000–3,000 pcs per style | ~3–5 weeks | ~50–80 days | Fabric + pocketing, construction changes, capacity |

| Denim 5-pocket jeans | Often 1,500–5,000 pcs per wash/color (wash MOQ matters) | ~3–6 weeks | ~60–90 days | Wash capacity, shade matching, chemical approvals |

| Denim jacket / outerwear | Often 800–2,000 pcs per style (higher if heavy wash) | ~4–7 weeks | ~70–100 days | Wash complexity, trims, sewing complexity |

| Woven dresses (non-knit) | Often 600–1,500 pcs per style | ~3–6 weeks | ~50–85 days | Fit approvals, printing/embroidery, fabric lead |

Fastest way to reduce lead time (before you ask for quotes)

- Approve faster: set internal deadlines for fit + lab dips + trims.

- Start with fewer colors/washes: add options after the first PO.

- Ask for stock/ready fabrics: best for first orders and testing.

- Confirm what “lead time” includes: ex-factory vs delivered to you (Incoterm).

Next: in the next section, you’ll see why MOQ is not “one number” and how to reduce it without compromising compliance or quality.

MOQ explained as a stack (why suppliers say “no”)

MOQ is rarely a factory “rule.” Most of the time it’s a combined minimum created by upstream suppliers (fabric mills, dyeing/finishing, washing, trims, and packing). If you understand the stack, you can reduce MOQ without pushing the factory into risk.

Buyer tip: Ask the supplier which layer is driving MOQ (fabric? wash? trims?). Then you can solve the real bottleneck instead of negotiating blindly.

| MOQ layer | What drives it | Common MOQ pressure point | How buyers reduce it (safe ways) |

|---|---|---|---|

| Fabric mill MOQ | Mill minimum weaving/knitting run + yarn allocation | Custom fabric specs, special compositions, unique finishes | Use stock/ready fabric, reduce colorways, align specs to mill’s standard base |

| Dyeing / finishing MOQ | Batch sizes for dyeing + finishing machines | Multiple shades, small lots, strict shade tolerance | Start with 1–2 core colors, approve shade quickly, consolidate similar shades |

| Denim wash MOQ | Washer capacity + chemical recipe setup + shade matching | Complex washes, heavy effects, many wash variations | Begin with one proven wash, add variations later, simplify effects for first PO |

| Trims MOQ | Buttons, zippers, labels, rivets, embroidery thread MOQs | Custom hardware, unique branding, special finishes | Use standard trims for first run, keep branding to labels/hangtags initially |

| Print/embroidery MOQ | Setup cost + screen count + machine efficiency | Many placements, many colors, high stitch counts | Reduce placements/colors, use smaller artwork, consolidate embroidery across styles |

| Packing MOQ | Polybag size, carton printing, sticker/hangtag runs | Custom carton print, multiple pack configurations | Use standard cartons, label by sticker first, keep packing simple for trial |

| Factory line MOQ | Line setup + learning curve + efficiency | Very complex styles, low repeatability, tight delivery window | Combine sizes/colors, commit to repeat order, allow realistic learning curve |

The 6 buyer moves that reduce MOQ fastest (without hurting quality)

- Start with a “pilot”: one wash / one fabric / fewer colors → expand after performance is proven.

- Choose stock fabric or mill-standard base: reduces mill MOQ pressure immediately.

- Consolidate components: same buttons/zippers/labels across multiple styles.

- Keep wash simple for denim trials: fewer effects = fewer reworks + faster approvals.

- Confirm MOQ by layer: ask “Is MOQ driven by fabric, wash, or trims?”

- Plan repeatability: suppliers accept lower MOQ when there’s a clear reorder path.

Want us to calculate MOQ & lead time from your tech pack?

Share your product type (woven/denim), fabric spec, target quantity, and delivery window — we’ll reply with a realistic MOQ breakdown and a timeline to ex-factory.

Next: let’s lock the buyer playbook — how to shorten lead time and prevent delays in Bangladesh orders.

How to reduce MOQ and shorten lead time (buyer playbook)

You can’t control everything, but you can control the biggest levers: clarity of tech pack, speed of approvals, fabric strategy, wash complexity (denim), and production planning. Use the actions below to reduce both MOQ pressure and timeline risk.

What you control (do these first)

- Approval speed: set internal deadlines for fit, lab dips, trims, PP sample.

- Style complexity: simplify construction for first PO; add features later.

- Wash strategy (denim): start with one proven wash; avoid too many variations.

- Fabric strategy: ask for stock/ready fabrics or mill-standard bases.

- Color strategy: begin with fewer core colors; expand after reorder.

What you can’t fully control (plan buffer)

- Mill production slots during peak seasons.

- Factory capacity when large brands are booking lines.

- Port + shipping space fluctuations.

- Customs/documentation timing by route and carrier.

- Weather disruptions affecting logistics.

10 tactics that reliably cut delays (in Bangladesh programs)

- Send a complete tech pack (measurements, BOM, construction, artwork placements, labels/packaging, testing needs).

- Lock your critical path: lab dips → trims → PP sample → bulk fabric → cutting.

- Use fewer wash variations for denim in your first order (wash approval is a common delay).

- Consolidate components (same zipper/button/label across styles) to reduce trims MOQ and delays.

- Pre-approve packing early (polybag, size sticker, carton marks, hangtags).

- Agree inspection plan (AQL level, inline + final inspection) before bulk starts.

- Confirm fabric lead time separately (mill booking is often the true driver).

- Ask for a capacity reservation once sampling is approved (avoid “queue” delays).

- Set approval SLAs: e.g., “We approve within 48 hours” (and stick to it).

- Add buffer where it matters: new fabric, new wash, new supplier = bigger buffer.

Need a realistic timeline for your order?

Send your product type (woven/denim), fabric spec, target quantity, target ship date, and destination country. We’ll reply with a practical timeline and MOQ breakdown.

Next: copy/paste the buyer checklist — it makes RFQs faster and quotes more accurate.

Buyer checklist (copy/paste)

If you want fast, accurate quotes (and fewer delays), send this checklist with your inquiry. It reduces back-and-forth and helps suppliers confirm a realistic MOQ + timeline.

RFQ essentials (send these)

- Product type: woven shirt / chinos / denim jeans / denim jacket (and target gender/fit)

- Tech pack: measurements, construction, BOM, artwork placements

- Order quantity: total qty + color breakdown + size ratio

- Fabric spec: composition, GSM/oz, weave, finish (or “open to supplier standard”)

- Denim wash (if denim): wash name + reference photos + tolerance notes

- Trims: zipper/button/rivets/labels (custom vs standard)

- Packaging: polybag, size sticker, carton marks, hangtags

- Target ship date: and destination country

- Incoterm: FOB / CFR / DDP (or ask supplier to recommend)

- Compliance needs: WRAP / BSCI / SEDEX / RSC / OEKO-TEX / others (only if required)

- Testing needs: colorfastness, azo, nickel, CPSIA/REACH (if relevant)

To speed approvals (do this)

- Set a rule: approve within 48 hours for fit/lab dips/trims when possible.

- Start with fewer colors/washes on the first PO.

- Confirm if the quoted lead time is ex-factory or delivered.

Resources & tools

Use these to estimate MOQ faster and compare lead times using real sourcing benchmarks.

Sources (for logistics context)

FAQs

These FAQs are written to be short and schema-friendly (good for Rank Math FAQ).

What is a realistic lead time for Bangladesh garments?

Most programs should plan lead time as development + bulk production + logistics. Repeat orders usually run faster than new styles because approvals are reduced. Always confirm whether the supplier is quoting ex-factory or delivered.

Why is MOQ higher for denim than woven?

Denim MOQ is often driven by wash capacity, shade consistency, and recipe setup. Multiple washes and heavy effects typically increase MOQ pressure and approvals time.

Can I start with a small MOQ in Bangladesh?

Sometimes, yes — especially if you use stock fabric, reduce colorways, and choose standard trims. The best approach is a pilot order with simple specs and a clear reorder plan.

What delays production the most?

The most common delays come from slow approvals, fabric booking, and capacity planning. For denim, wash approvals and shade matching are frequent critical-path items.

Does Incoterm change lead time?

Yes. FOB usually ends at ex-factory/port handover, while CFR/DDP includes more logistics steps. Always align “lead time” to the Incoterm you’re using.

What should I send for accurate quoting?

Send a complete tech pack, fabric spec, total qty with color/size breakdown, wash details (for denim), packaging needs, target ship date, destination, and Incoterm. This reduces back-and-forth and improves quote accuracy.

Ready to source? Get a realistic MOQ + lead time reply

Tell us your product (woven/denim), target quantity, fabric spec, wash (if denim), and target ship date. We’ll reply with an MOQ breakdown and a practical timeline.