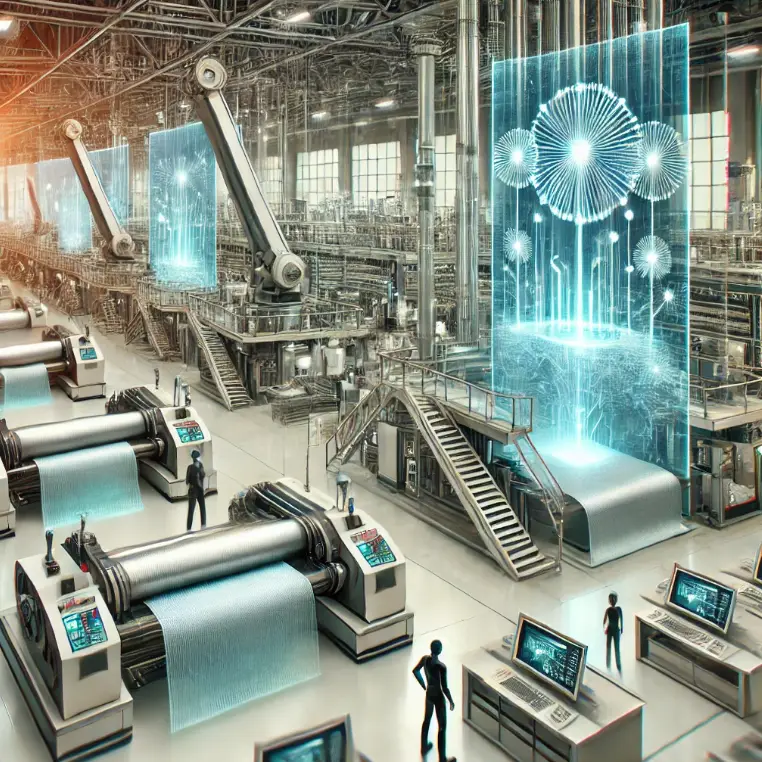

The textile industry, once dominated by traditional manual processes, has evolved into a highly automated and technologically advanced sector. Today’s global textile industry operates with sophisticated machinery and systems that manage all four critical stages of production: fiber processing, fabric manufacturing, finishing, and the creation of innovative textile products. With continued advancements in technology, the textile industry is undergoing significant transformations that enhance product functionality, sustainability, and production efficiency.

Automation and Advanced Manufacturing

Moreover, the scale of production has expanded, with factories often able to manage multiple production stages simultaneously. This integration of processes allows for faster turnaround times and improved coordination between different stages of textile production.

Technological Innovations in Textiles

One of the most exciting developments in the textile industry is the creation of textiles with advanced functionalities. Technological innovations have led to the development of smart textiles that are embedded with electronics, offering a wide range of potential applications.

For instance, optical fibers with integrated electronics allow textiles to sense, process, and store data. These innovative fibers can be woven into fabrics to create garments with advanced capabilities, such as military uniforms with embedded sensors, medical textiles that monitor health, and high-performance athletic wear designed to optimize performance.

This new generation of fabrics is not limited to aesthetics and comfort. They also provide additional functionality, allowing textiles to interact with the environment and even respond to various stimuli, such as temperature, light, or pressure. These advanced textiles are revolutionizing industries such as defense, healthcare, and sportswear, providing unique solutions that were once unimaginable.

Proprietary Fibers and Performance Fabrics

To meet the evolving needs of consumers, many textile companies are developing proprietary fibers designed for specific purposes. These fibers are engineered to enhance the performance of textiles in certain applications, whether for comfort, durability, or technical functionality.

For example, Brooks Brothers has introduced BrooksCool®, a fabric made from 100% cotton but treated to enhance its breathability, ensuring that it remains comfortable even in warm weather. On the other hand, Nike’s Dri-FIT fabric, a high-performance microfiber polyester, is designed to wick moisture away from the body, keeping athletes dry and comfortable during intense physical activity.

Such proprietary fabrics help brands cater to specific consumer needs, ensuring that their products stand out in an increasingly competitive market. These fabrics are developed using extensive research and development and are often protected by patents to maintain their exclusivity in the market.

Sustainability and Environmental Responsibility

In recent years, the textile industry has been under increasing scrutiny regarding its environmental impact. With textile manufacturing processes consuming large amounts of water, energy, and raw materials, companies are now focusing on adopting sustainable practices that minimize their ecological footprint.

One of the key areas of focus is water and energy conservation. Textile companies are investing in technologies that reduce the amount of water and energy used during production, particularly in processes such as dyeing and finishing, which are traditionally resource intensive.

Additionally, recycling has become an essential part of the industry’s sustainability efforts. Many companies are now recycling raw materials such as water, energy, and even waste products like plastic and paper. Recycling helps reduce the demand for new resources, lowering the environmental impact of textile production.

Another emerging trend is the use of sustainable materials in textile manufacturing. Companies are exploring the use of organic fibers, biodegradable materials, and recycled fabrics in the creation of their products. This commitment to sustainability is driven by consumer demand for eco-friendly products and a growing awareness of the need to protect the environment.

The Future of the Textile Industry

The future of the textile industry looks bright, with continued innovation and sustainability at the forefront of industry developments. As technology advances, we can expect to see more intelligent textiles that incorporate features such as self-cleaning capabilities, energy-generating fabrics, and garments that adapt to environmental conditions.

The integration of automation and artificial intelligence will further improve production processes, reducing waste and increasing efficiency. The focus on sustainability will also continue, with companies exploring new ways to reduce their environmental impact and adopt circular economy practices.

Conclusion

The textile industry is rapidly evolving, driven by innovations in automation, performance fabrics, and sustainable practices. The development of smart textiles and proprietary fibers has opened new possibilities for industries such as defense, healthcare, and sportswear. At the same time, the industry is prioritizing sustainability, focusing on reducing resource consumption and waste. As technology continues to advance, the textile industry will remain at the forefront of change, providing consumers with more functional, comfortable, and eco-friendly products.

By embracing these innovations and sustainability efforts, textile companies are positioning themselves to meet the demands of the future, ensuring that they remain competitive in a dynamic and fast-changing market.

Social Share